Food Manufacturing Inventory Management

Software

Know where your food manufacturing assets and equipment are at all times with InVentry’s food manufacturing inventory software.

A simple, cost-effective way to manage assets in your food manufacturing business

InVentry’s food manufacturing inventory software is a specialised solution designed to manage and optimise inventory-related processes within food production businesses. Our inventory software for food manufacturing businesses offers the tracking, control, and analysis of all inventory items and ingredients crucial for food manufacturing, including raw materials, packaging materials, finished products, and perishable goods.

Our inventory software for food manufacturing businesses provides real-time visibility into inventory levels, helps ensure compliance with food safety regulations, assists with batch and lot tracking, streamlines production planning, and enables efficient order fulfilment and demand forecasting.

Request a brochure today and take a look at how InVentry can help your organisation.

Types of Assets

Types Of Manageable Food Manufacturing Assets

Food manufacturing assets typically include a wide range of physical items and resources that are essential for the smooth functioning of producing specific food products. InVentry’s food manufacturing inventory management software can help manage common types of factory assets that include:

Ingredients

e.g. flour, sugar, salt, spices, and flavourings.

Packaging containers

e.g. bottles, cans, jars, cartons, and bags.

Labels, Stickers & Packaging Materials

e.g. plastic wrap, foil, and sealing materials.

Packaged and Labelled Food Products Ready for Distribution and Sale

Semi-processed Goods at Various Stages of Production

Shelving, Racks, and Pallets

For organising and storing inventory

Refrigeration Units and Cold Storage Facilities

Food Processing Machinery

e.g. mixers, grinders, ovens, and cookers, cutting, slicing, and packaging machines.

Testing Equipment for Measuring Factors

e.g. pH, temperature, and moisture.

Tools for Visual Inspection & Quality Assurance

Personal Protective Equipment (PPE)

for employees and visitors.

Fire Extinguishers, Safety Signs & Emergency Response Supplies

Tools and Equipment for Maintaining and Repairing Machinery & Facilities.

Cleaning Goods

e.g. chemicals, detergents, and sanitisers, bins, containers, and equipment for waste disposal and recycling.

Vehicles & Transportation Equipment

Food Safety and Compliance Records

Replacement Parts for Machinery and Equipment

to minimise downtime

Regulatory Documents, Certifications & Compliance Records.

Training Materials, Manuals & Resources

for staff development and compliance with food safety standards.

Benefits of using food manufacturing inventory management software

A food manufacturing inventory software offers food manufacturing organisations the chance to operate more efficiently. By reducing operational costs, maintaining compliance with legislation, and enabling data-driven decisions, production companies can improve productivity and resource management. InVentry’s inventory software for food manufacturing offers many benefits, including:

Enhanced Food Safety

Inventory management software helps track and manage inventory items with expiration dates, enabling better control over the shelf life of products.

Enhanced Regulatory Compliance

The inventory software for food manufacturing businesses can help food manufacturers comply with various regulatory requirements, such as those related to food safety, labelling, and traceability.

Improved Traceability

The food manufacturing asset management software allows for precise batch and lot tracking, making it easier to trace the origin and movement of ingredients and products.

Reduced Food Waste

By providing real-time visibility into inventory levels and expiration dates, the software helps minimise food waste.

Efficient Production Planning

Food manufacturing inventory software offers insights into material availability, enabling more efficient production planning and scheduling resulting in reduced lead times.

Cost Savings

Optimising inventory levels and reducing waste leads to cost savings.

Accurate Forecasting

With historical data and demand forecasting features, the food manufacturing inventory management software aids in predicting customer demand patterns.

Inventory Accuracy

Automation reduces manual errors in data entry and inventory tracking

Data-Driven Decision-Making

The food manufacturing inventory management software provides valuable data and analytics, enabling data-driven decision-making.

Food Manufacturing Inventory Software Features

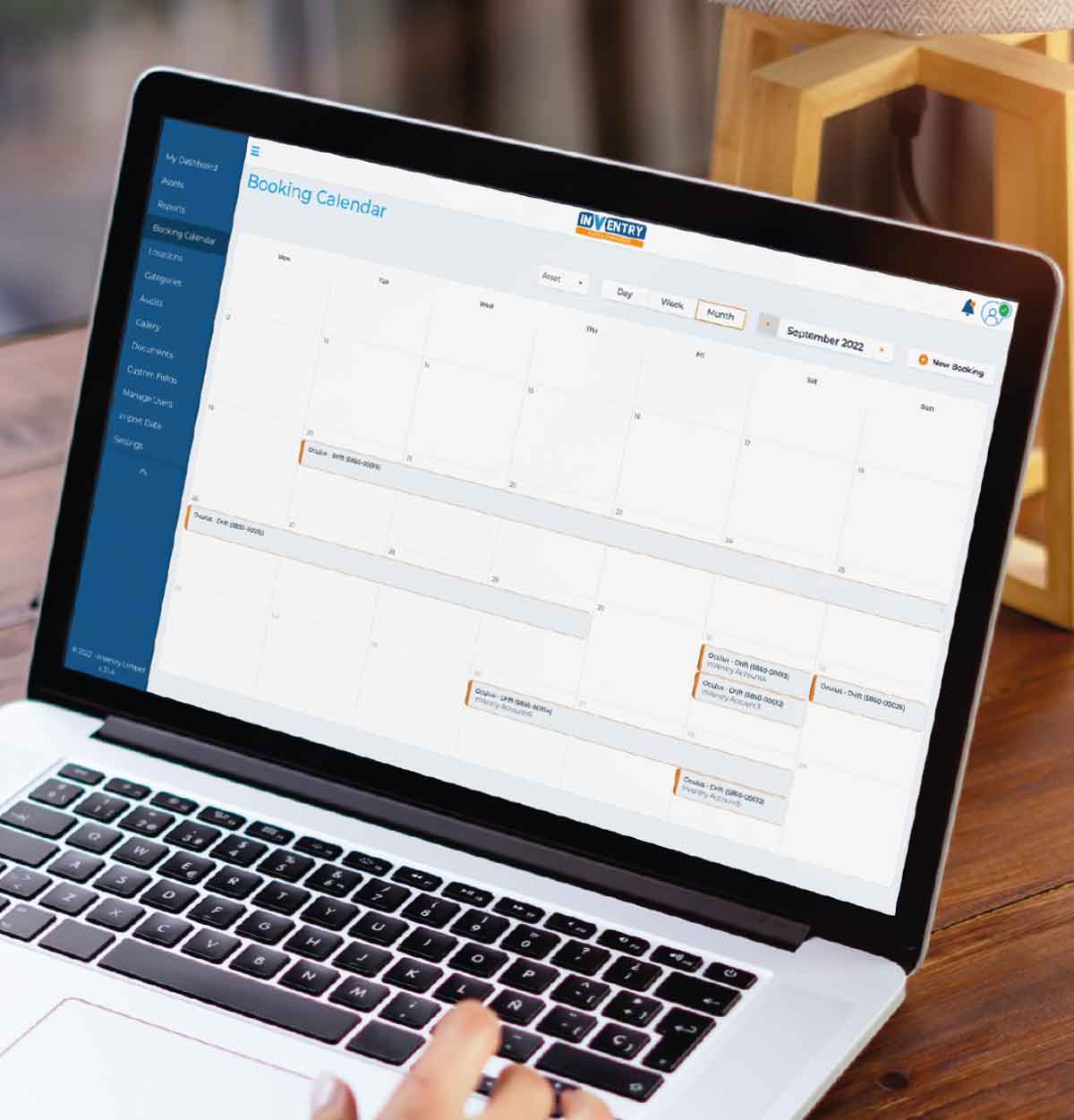

Custom Reports

Our asset management system for food manufacturers is intuitive and easy to use; allowing you to export reports in PDF or CSV formats.

Document Storage

See current and previous asset locations at a glance in the office asset management software.

Disaster Recovery

Enjoy peace of mind with secure, cloud-based asset data storage with our inventory software for food manufacturing businesses.

Fault Reporting

Easily report faults with equipment by scanning its QR code.

Loan Equipment

See current and previous asset locations at a glance in the food factory asset tracking software.

Training and Support

Contact our full UK support team with any InVentry manufacturing inventory tracking software questions or queries.

Audit Labels

Use audit labels, included in your package, throughout the duration of your asset audit software subscription.

MAT Asset Solution

Access asset information from multiple sites using your food manufacturing inventory software login.

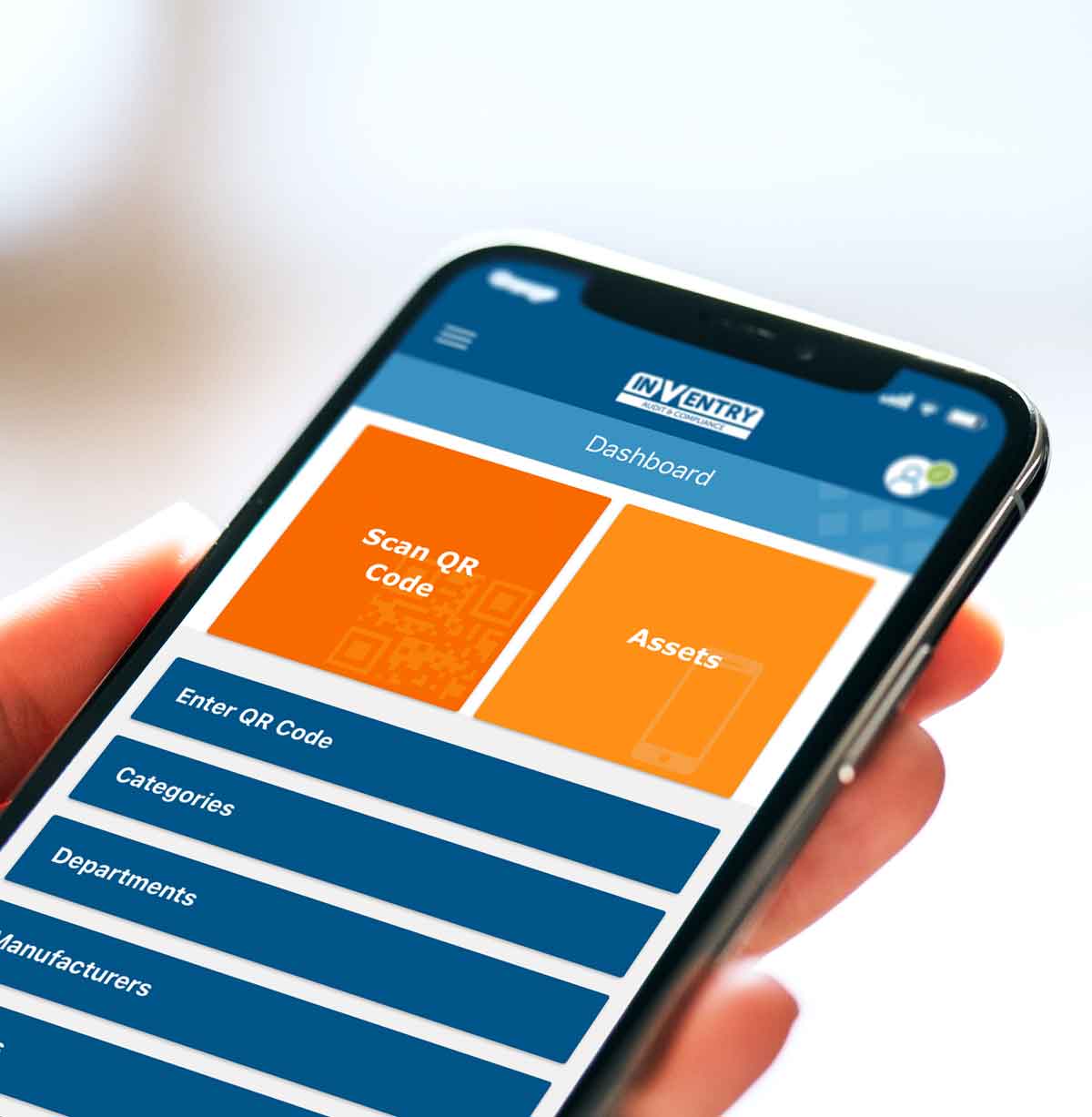

How Our Asset Tracking Program Works

Simple

Scan the QR code using the food manufacturing inventory management software app to quickly add assets and locations.

Smart

Our simple food manufacturing inventory software allows you to change assets on the go, report faults, or remove redundant assets at will.

Effective

Use InVentry’s food manufacturing inventory management software app to produce asset management audit reports, make bulk changes and see the value of your food manufacturing assets.

Meet Some Of Our Existing Asset Management Customers

Testimonials

See some examples of what our customers have to say about InVentry. For even more, visit our testimonials page.

We were delighted with InVentry’s quick turn over and the software’s ability to read 3rd party labels was a bonus for us as it meant there was very little disruption for our clients. The ability to scan our assets via a mobile device is extremely important for our line of work and the ability to sync everything via the cloud has made deliveries to clients as simple as possible.

The layout and functionality of the system is easy to use which enables us to get the job done as quick and effectively as possible. We’re able to track every asset even when our products are across many different sites at any one time.

– McAuliffe Site Services

Contact Us

Want To Know About Our Food Manufacturing Inventory Software? Contact Us.

Request a brochure, or book your free demo of our Food Manufacturing Inventory Software today and find out how your business can benefit from our food manufacturing asset management software.

- 0113 322 9253

- info@inventry.co.uk

-

InVentry Ltd

Visitor House,

Gelderd Road,

Gildersome,

Leeds, LS27 7JN

Looking for support? Please use our support form